Description

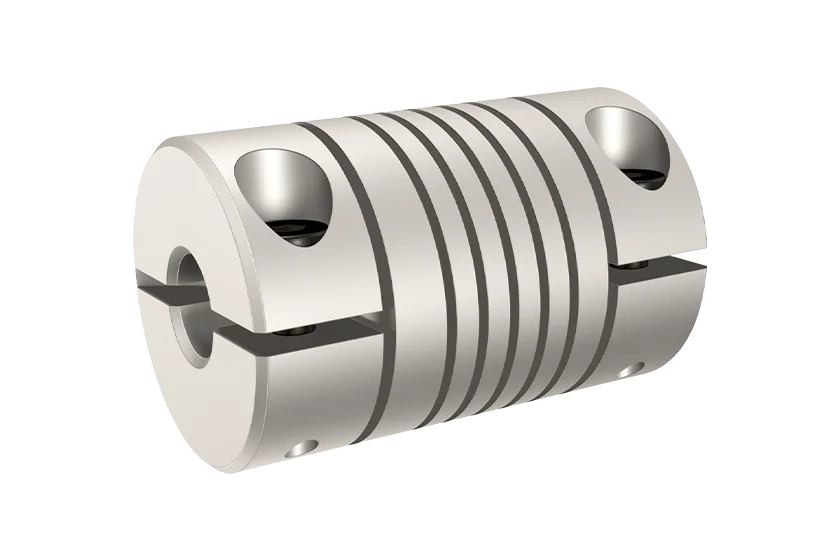

Spiral couplings made of aluminum – compact compensating couplings for precise torque transmission

Our aluminum spiral couplings ensure backlash-free power transmission and effective misalignment compensation in compact drive systems. Whether in automation, linear motion, or highly dynamic servo axes – these couplings operate reliably even in tight installation spaces.

Technical data

| Designation | Model | d1 (mm) | d2 (mm) | Outer diameter (mm) | Installation length (mm) | Max. torque (Ncm) | Max. speed (min⁻¹) | Max. radial shaft misalignment (mm) | Max. axial shaft misalignment (mm) | Max. angular shaft offset (degrees) | Torsional spring stiffness (Nm/rad) | Radial spring stiffness (N/mm) | Moment of inertia (gcm²) | Max. screw torque (Ncm) | Temperature range (°C) | Weight approx. (g) | material |

| WKAS 1622 03/03 | WKAS 1622 | 3 | 3 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 03/04 | WKAS 1622 | 3 | 4 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 03/05 | WKAS 1622 | 3 | 5 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 04/04 | WKAS 1622 | 4 | 4 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 04/05 | WKAS 1622 | 4 | 5 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 05/05 | WKAS 1622 | 5 | 5 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1622 06/06 | WKAS 1622 | 6 | 6 | 16 | 22 | 40 | 8000 | ± 0.2 | ± 0.3 | ± 3 | 5 | 34 | 3.2 | 80 | -30 to +150 | 9.5 | aluminum |

| WKAS 1922 05/05 | WKAS 1922 | 5 | 5 | 19 | 22 | 60 | 8000 | ± 0.25 | ± 0.4 | ± 3.5 | 9 | 40 | 6.7 | 80 | -30 to +150 | 13 | aluminum |

| WKAS 1922 06/06 | WKAS 1922 | 6 | 6 | 19 | 22 | 60 | 8000 | ± 0.25 | ± 0.4 | ± 3.5 | 9 | 40 | 6.7 | 80 | -30 to +150 | 13 | aluminum |

| WKAS 1922 06/08 | WKAS 1922 | 6 | 8 | 19 | 22 | 60 | 8000 | ± 0.25 | ± 0.4 | ± 3.5 | 9 | 40 | 6.7 | 80 | -30 to +150 | 13 | aluminum |

| WKAS 1922 08/08 | WKAS 1922 | 8 | 8 | 19 | 22 | 60 | 8000 | ± 0.25 | ± 0.4 | ± 3.5 | 9 | 40 | 6.7 | 80 | -30 to +150 | 13 | aluminum |

| WKAS 2524 06/06 | WKAS 2524 | 6 | 6 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 06/08 | WKAS 2524 | 6 | 8 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 06/10 | WKAS 2524 | 6 | 10 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 08/08 | WKAS 2524 | 8 | 8 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 08/10 | WKAS 2524 | 8 | 10 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 10/10 | WKAS 2524 | 10 | 10 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 10/12 | WKAS 2524 | 10 | 12 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2524 12/12 | WKAS 2524 | 12 | 12 | 25 | 24 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 20 | 60 | 22.2 | 120 | -30 to +150 | 26 | Aluminum not anodized |

| WKAS 2532 06/06 | WKAS 2532 | 6 | 6 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 06/08 | WKAS 2532 | 6 | 8 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 06/10 | WKAS 2532 | 6 | 10 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 08/08 | WKAS 2532 | 8 | 8 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 08/10 | WKAS 2532 | 8 | 10 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 10/10 | WKAS 2532 | 10 | 10 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 10/12 | WKAS 2532 | 10 | 12 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAS 2532 12/12 | WKAS 2532 | 12 | 12 | 25 | 32 | 100 | 8000 | ± 0.3 | ± 0.5 | ± 4 | 18 | 50 | 30 | 120 | -30 to +150 | 35 | anodized aluminum |

| WKAK 1421 02/02 | WKAK 1421 | 2 | 2 | 14 | 21 | 50 | 8000 | ± 0.2 | ± 0.25 | ± 3 | 4.5 | 22 | 1.9 | 50 | -30 to +150 | 6.5 | anodized aluminum |

| WKAK 1421 02/03 | WKAK 1421 | 2 | 3 | 14 | 21 | 50 | 8000 | ± 0.2 | ± 0.25 | ± 3 | 4.5 | 22 | 1.9 | 50 | -30 to +150 | 6.5 | anodized aluminum |

| WKAK 1421 03/03 | WKAK 1421 | 3 | 3 | 14 | 21 | 50 | 8000 | ± 0.2 | ± 0.25 | ± 3 | 4.5 | 22 | 1.9 | 50 | -30 to +150 | 6.5 | anodized aluminum |

| WKAK 1421 03/04 | WKAK 1421 | 3 | 4 | 14 | 21 | 50 | 8000 | ± 0.2 | ± 0.25 | ± 3 | 4.5 | 22 | 1.9 | 50 | -30 to +150 | 6.5 | anodized aluminum |

| WKAK 1421 04/04 | WKAK 1421 | 4 | 4 | 14 | 21 | 50 | 8000 | ± 0.2 | ± 0.25 | ± 3 | 4.5 | 22 | 1.9 | 50 | -30 to +150 | 6.5 | anodized aluminum |

| WKAK 1625 03/03 | WKAK 1625 | 3 | 3 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1625 03/05 | WKAK 1625 | 3 | 5 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1625 04/04 | WKAK 1625 | 4 | 4 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1625 04/06 | WKAK 1625 | 4 | 6 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1625 05/05 | WKAK 1625 | 5 | 5 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1625 05/06 | WKAK 1625 | 5 | 6 | 16 | 25 | 60 | 6000 | ± 0.2 | ± 0.3 | ± 3.5 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 04/04 | WKAK 1928 | 4 | 4 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 04/06 | WKAK 1928 | 4 | 6 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 05/05 | WKAK 1928 | 5 | 5 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 05/06 | WKAK 1928 | 5 | 6 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 05/63 | WKAK 1928 | 5 | 6.35 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 06/06 | WKAK 1928 | 6 | 6 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 06/63 | WKAK 1928 | 6 | 6.35 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 1928 63/63 | WKAK 1928 | 6.35 | 6.35 | 19 | 28 | 80 | 6000 | ± 0.25 | ± 0.4 | ± 4 | 8 | 36 | 8.7 | 120 | -30 to +150 | 16 | anodized aluminum |

| WKAK 2532 06/06 | WKAK 2532 | 6 | 6 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 06/63 | WKAK 2532 | 6 | 6.35 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 06/08 | WKAK 2532 | 6 | 8 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 06/95 | WKAK 2532 | 6 | 9.52 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 06/10 | WKAK 2532 | 6 | 10 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 08/08 | WKAK 2532 | 6.35 | 6.35 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 08/10 | WKAK 2532 | 6.35 | 8 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 10/10 | WKAK 2532 | 6.35 | 9.52 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 2532 10/12 | WKAK 2532 | 8 | 8 | 25 | 32 | 100 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 16 | 45 | 29 | 120 | -30 to +150 | 34 | anodized aluminum |

| WKAK 3038 08/08 | WKAK 3038 | 8 | 8 | 30 | 38 | 150 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 19 | 60 | 76 | 120 | -30 to +150 | 58 | anodized aluminum |

| WKAK 3038 10/10 | WKAK 3038 | 10 | 10 | 30 | 38 | 150 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 19 | 60 | 76 | 120 | -30 to +150 | 58 | anodized aluminum |

| WKAK 3038 10/12 | WKAK 3038 | 10 | 12 | 30 | 38 | 150 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 19 | 60 | 76 | 120 | -30 to +150 | 58 | anodized aluminum |

| WKAK 3038 12/12 | WKAK 3038 | 12 | 12 | 30 | 38 | 150 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 19 | 60 | 76 | 120 | -30 to +150 | 58 | anodized aluminum |

| WKAK 3038 14/14 | WKAK 3038 | 14 | 14 | 30 | 38 | 150 | 6000 | ± 0.35 | ± 0.5 | ± 4 | 19 | 60 | 76 | 120 | -30 to +150 | 58 | anodized aluminum |

Data sheet as PDF for download

📄 [Data sheet follows]

CAD model for download

🧩 Follow CAD models on Microsoft SharePoint

Product highlights

⭐️ Backlash-free power transmission: The spiral-milled structure enables precise, angular movement even during reversing load changes.

⭐️ Efficient misalignment compensation: Radial, axial and angular shaft misalignments (up to ±0.5 mm or ±4°) are reliably compensated.

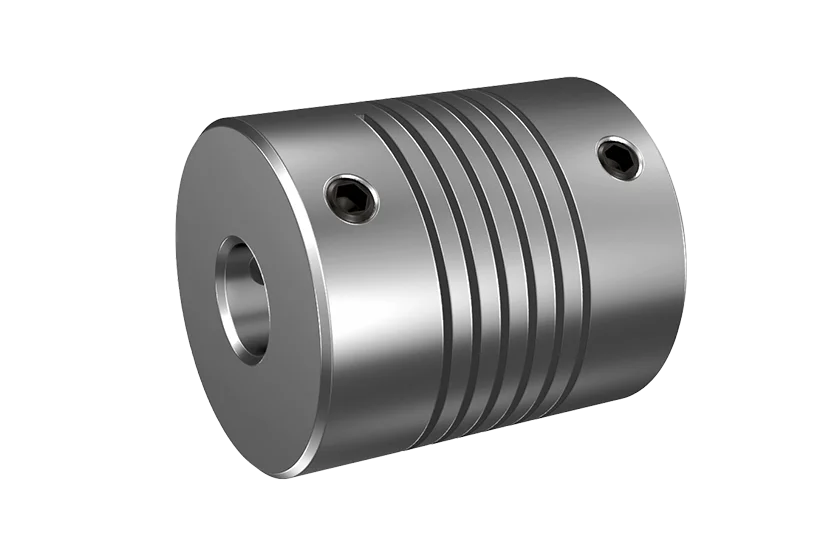

⭐️ Wide range of variants with small dimensions: outer diameters from 14 to 30 mm, lengths from 21 mm – ideal for tight installation conditions.

⭐️ High temperature resistance: Reliable from -30 °C to +150 °C – even in demanding environmental conditions.

⭐️ Fast availability from stock: Many common variants with screw fastening available at short notice – with bore combinations from 3 to 14 mm.

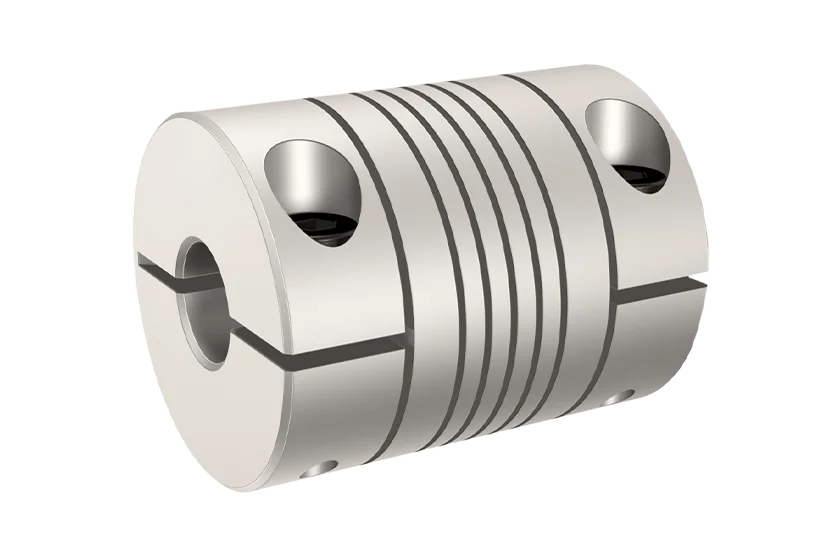

Technical advantages

✅ Torsionally stiff with low restoring force: Torsion spring stiffnesses of up to 20 Nm/rad enable precise control behavior in dynamic applications.

✅ Low moment of inertia: Depending on the size, from 1.9 gcm² – ideal for highly accelerated servo axes or incremental encoder applications.

✅ Robust lightweight construction: Made of high-quality aluminum – for low weight (e.g. only 6.5 g for WKAK 1421) and high load capacity up to 100 Ncm.

✅ Versatile bore diameters: Different hub bores (e.g. 6/8 mm or 10/12 mm) enable precise installation without adapters.

✅ Secure connection through screw fastening: For a backlash-free fit – also suitable for changing directions of rotation and high speeds up to 8000 min⁻¹.

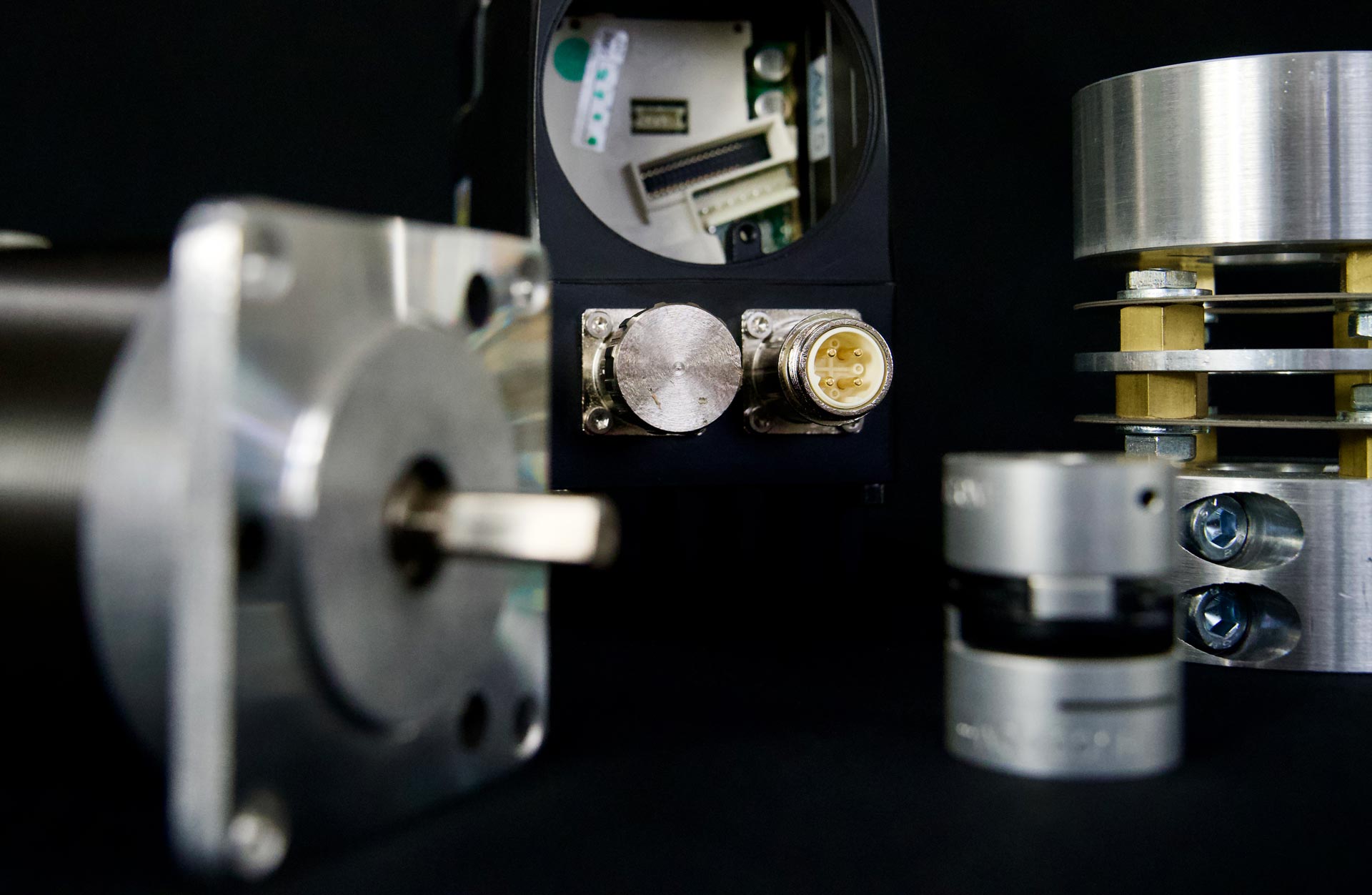

Typical application examples

Helical couplings of this type are used wherever compact compensating elements with high precision are required. These include:

⚙️ CNC machining centers and positioning systems

⚙️ Servo motor connections in automation systems

⚙️ Encoder connections for transmitting small torques

⚙️ Linear axes and handling systems in special machine construction

⚙️ Micromechanical drives with limited installation space

They solve typical challenges such as misalignment, shaft misalignment and backlash-free transmission under changing load conditions.

Do you need support?

Do you have questions about selecting the right spiral coupling or need a customized drilling pattern? We'd be happy to advise you personally. Contact us ↗

📞 Tel.: +49 [40] 5388921-0 (Mon - Thurs 8:00-16:30, Fri 8:00-16:00)

📧 Email: sales@tea-hamburg.de

Further information can be found on our homepage ↗